Shop

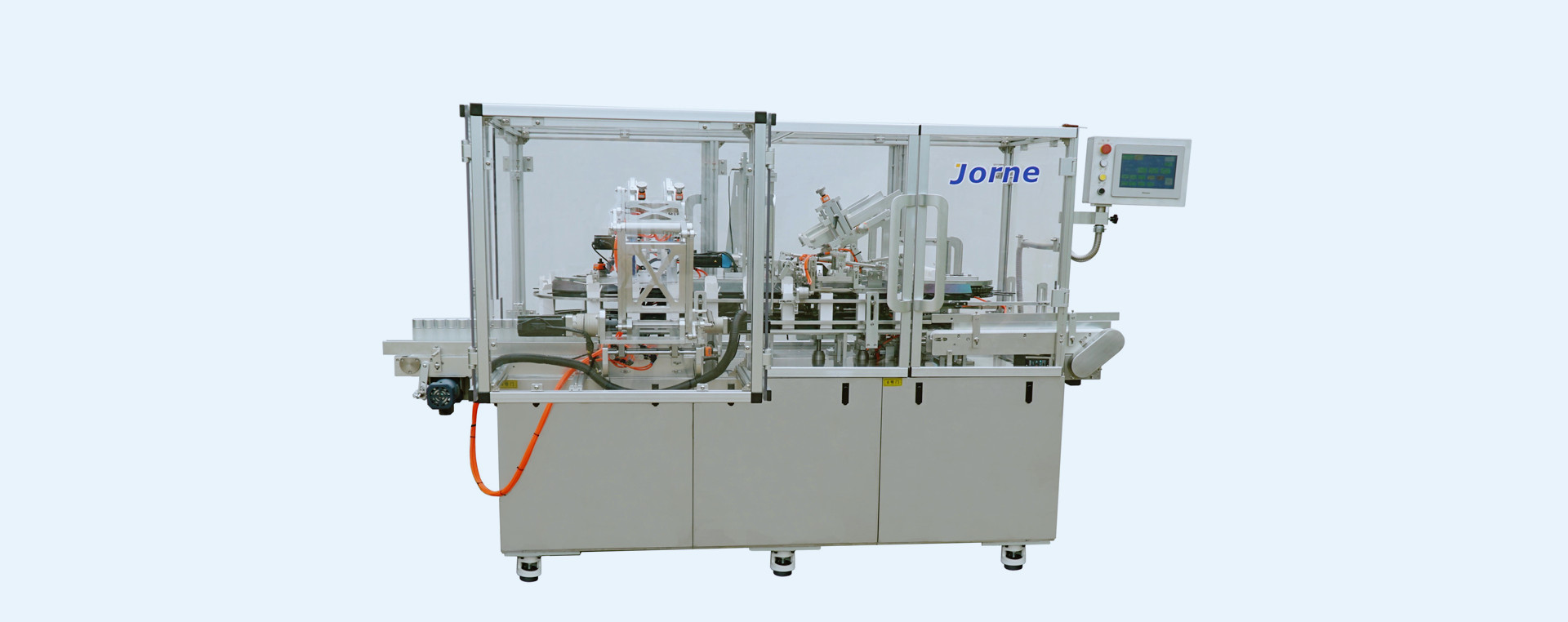

Jornen – Blister Machine

Description

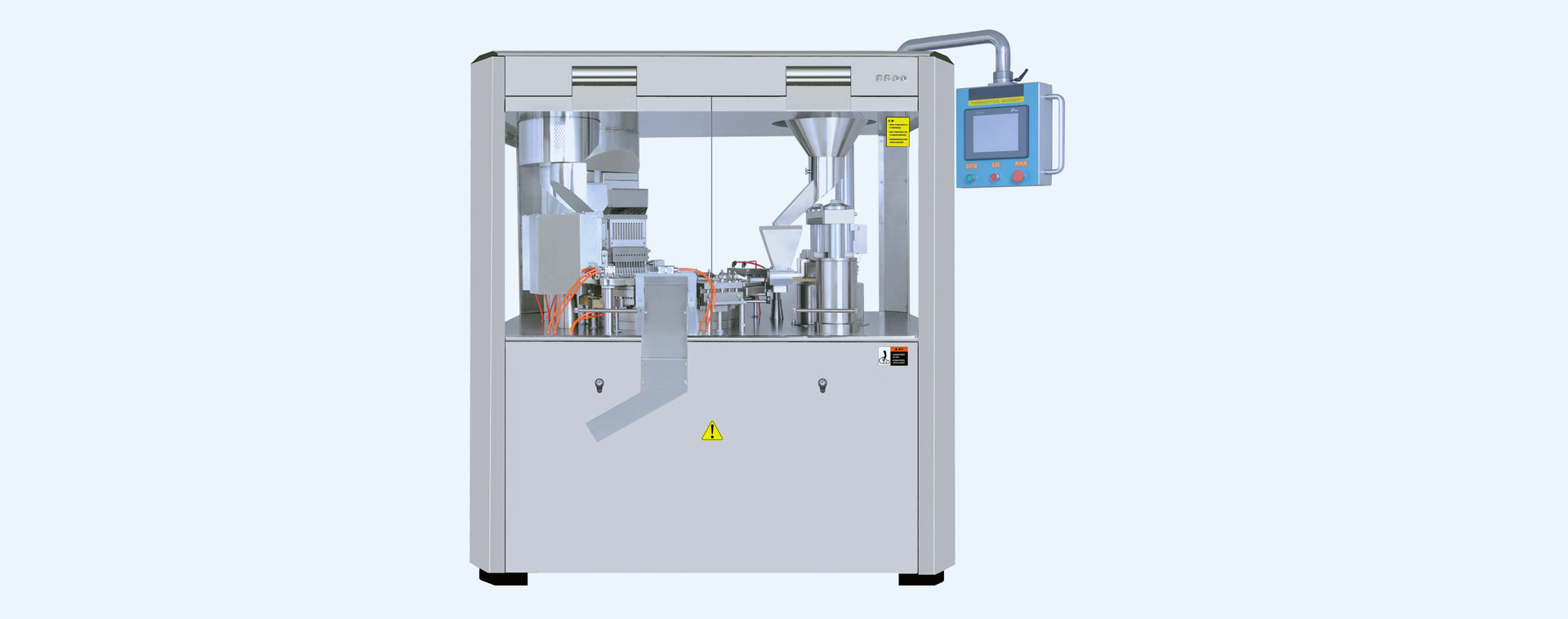

Blister Machine DPP260Ki-2 is the second generation of DPP260Ki.

· Equipped with automatic format locking, positioning system, achieves extremely straightforward format changeover (new).

·In the sealing station, when the machine stops, the heating sealing mould can rise up automatically, to prevent hot air from getting into the blister pockets, so that medicine effectiveness is preserved.

· Sealing pressure adopts the gas-hydraulic pressure cylinder, so the pressure can be set freely according to the sealing area (commonly a larger sealing area requires higher pressure) (new).

· All the main parts are made of premium stainless steel and alu-alloy material, and machined by advanced high precision CNC tooling machines.

· This machine accommodates two forming material reels. One of the reel’s diameter can reach up to 600mm, if it equips the waste material trimming cutter(optional), it could allow production runs of approximately 90 minutes, therefore, reducing the material replacement frequency.

· This machine is equipped with an integrated forming material splicer to enhance efficiency during material replacement.

· The upper and lower plates adopt contact heating method that significantly reduces the forming temperature. Thus the shrinkage, deforming of packaging material and power consumption are minimized.

· Using a fast lock method enables replacement of lidding material easily within 10 seconds.

· The blister length can be set freely through Touch Screen User Interface, which reduces the time for a format changeover.

.jpg)

Reviews

There are no reviews yet.